How to maintain UHMWPE Machined Parts

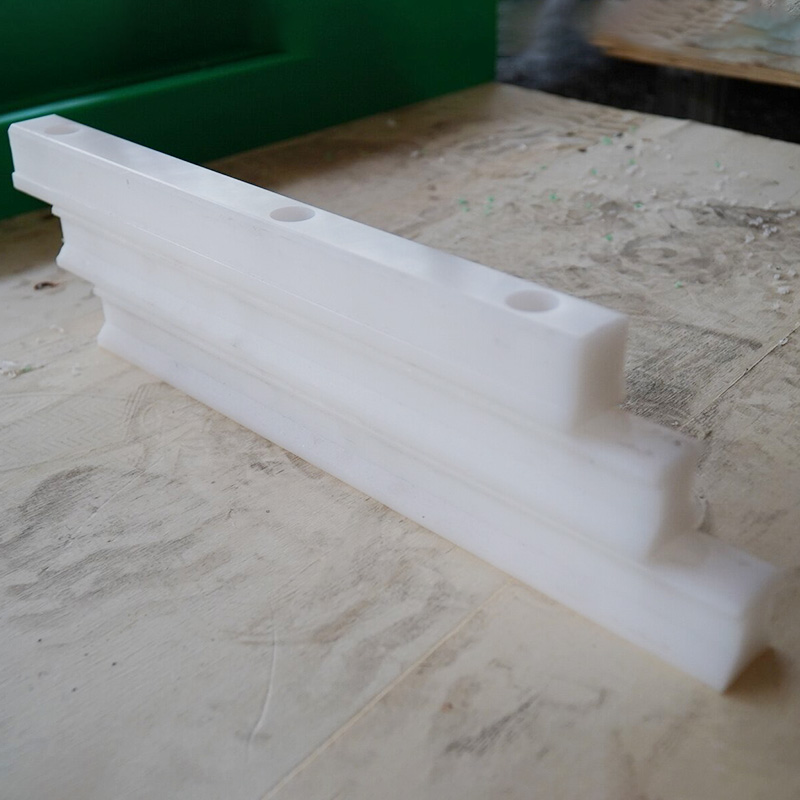

UHMWPE Machined Parts are widely used in many fields due to their outstanding wear resistance and self-lubricating properties. Good maintenance work can not only give full play to its performance advantages, but also greatly extend its service life. The following introduces specific maintenance points from four aspects: cleaning, inspection, avoiding abnormal force, and storage.

After daily use, dust, debris and oil on the surface should be removed in time to prevent pollutants from entering the surface micropores and reducing product performance. For ordinary dirt, just wipe it with a damp cloth dipped in a mild detergent. Like the scraper under the coal mine, after each shift, a damp cloth with a weak alkaline detergent can easily remove coal dust and mud. If you encounter stubborn stains, you can use a special polymer material cleaner, dilute it according to the instructions, and gently scrub it with a soft brush. Do not use sharp tools such as steel wool to avoid scratching the surface.

Regularly check the special-shaped parts to check whether there are scratches, cracks, deformations or wear on the surface. Once a small crack is found, it should be handled immediately. Taking the conveying pipeline as an example, an appearance inspection should be carried out at least once a month.

When installing UHMWPE Machined Parts, be sure to strictly follow the instructions to ensure accurate installation position and uniform force, and avoid forced assembly. During use, it is necessary to clarify its load-bearing capacity, reasonably control the material conveying volume, and prevent overload from accelerating wear.

UHMWPE Machined Parts that are not in use temporarily should be stored in a dry and ventilated environment, avoiding direct sunlight, high temperature and chemical corrosion. The ideal storage temperature is 10-30℃ and humidity is 40%-60%. In addition, it is necessary to use bubble film, sponge and other materials for protection and store them in wooden boxes or cartons.