What are the uses of UHMWPE Conveyor Wear Strips?

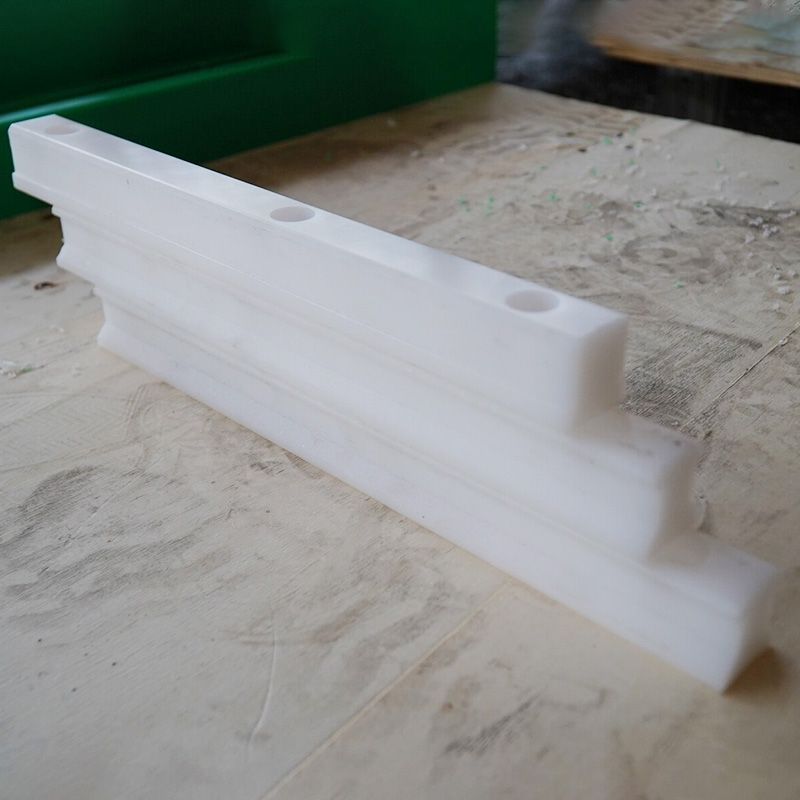

UHMWPE Conveyor Wear Strips, also known as conveyor scraper, are widely used in many fields because of their unique physical and chemical properties, especially those requiring high wear resistance, high impact resistance and low friction coefficient. The following are the main uses of UHMWPE Conveyor Wear Strips:

1. Mining, cement, steel and other industries: In these industries, UHMWPE Conveyor Wear Strips are used to transport ore, coal, cement, slag and other materials. They can withstand heavy loads and shocks in harsh operating environments, while being self-lubricating to reduce equipment wear and friction.

2. Logistics industry: In the logistics industry, UHMWPE Conveyor Wear Strips are used in conveyor belts, stevedors and other equipment for material conveying, sorting and other operations.

3. Food industry: In the food industry, because ultra-high molecular weight polyethylene has the characteristics of non-toxic, tasteless and no exudate, it is used for conveying machinery and equipment on food processing production lines such as food, beverages, candy, bread, etc.

4. Medical industry: In the medical industry, UHMWPE Conveyor Wear Strips are used in operating rooms, wards, surgical instruments, mattresses, wheelchairs and other equipment, as well as artificial joints, teeth and other medical instruments.

In short, UHMWPE Conveyor Wear Strips are widely used in machinery manufacturing, medical equipment, food processing, logistics equipment and other fields because of its wear resistance, impact resistance, chemical corrosion resistance, self-lubrication and other characteristics.