What is the best material for chain guides?

As an important part of the mechanical transmission system, the material selection of the chain guide rail is directly related to the efficiency and stability of the whole system. So, What is the best material for chain guides?

At present, the common chain guide materials on the market include plastics, metals and composite materials. Below we will introduce the characteristics of these materials:

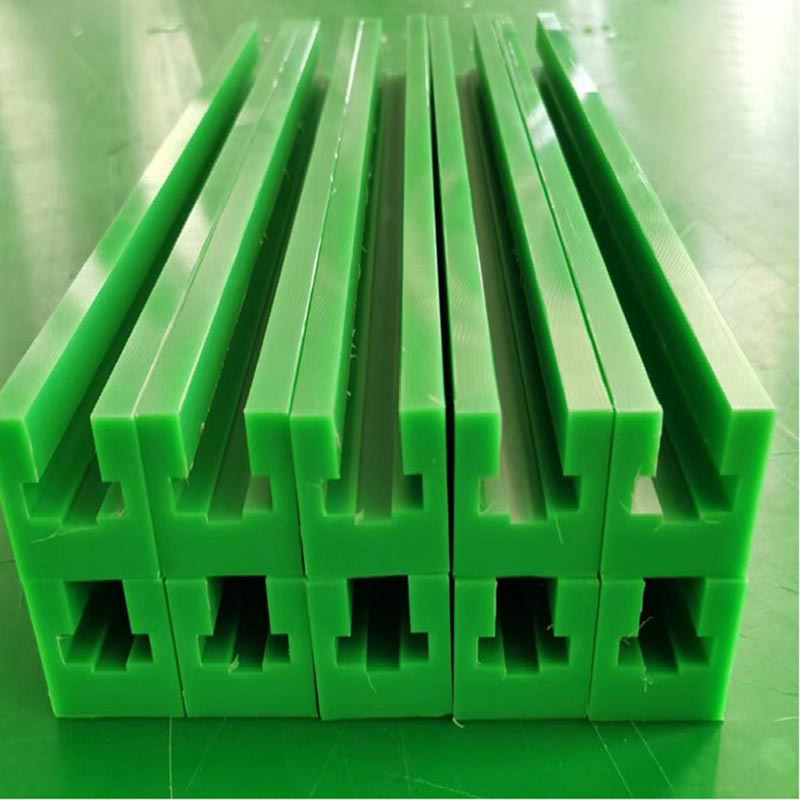

Plastic material: Plastic chain guide has the advantages of light weight, easy processing and low cost. In addition, some engineering plastics such as nylon, polyformaldehyde, etc., also have good wear resistance and corrosion resistance. However, plastic guides are prone to deformation and wear under high temperature and heavy load conditions, which limits their application range.

Metal materials: Metal materials such as steel, aluminum alloy, etc., have high strength and stiffness, and can withstand large loads and shocks. At the same time, the wear resistance and fatigue resistance of the metal guide rail are also good. However, the disadvantages of metal guide rail are large weight, high processing difficulty, high cost, and easy to rust in some corrosive environments.

Composite materials: Composite chain guides combine the advantages of plastic and metal, both with light weight and good processing performance, but also with high strength and wear resistance. In addition, the composite material also has good corrosion resistance and is suitable for a variety of harsh environments. However, the cost of composite materials is relatively high and the production process is complex.

In summary, the best material for the chain guide depends on the specific application scenario and needs.