What is the best plastic for Chain Guides

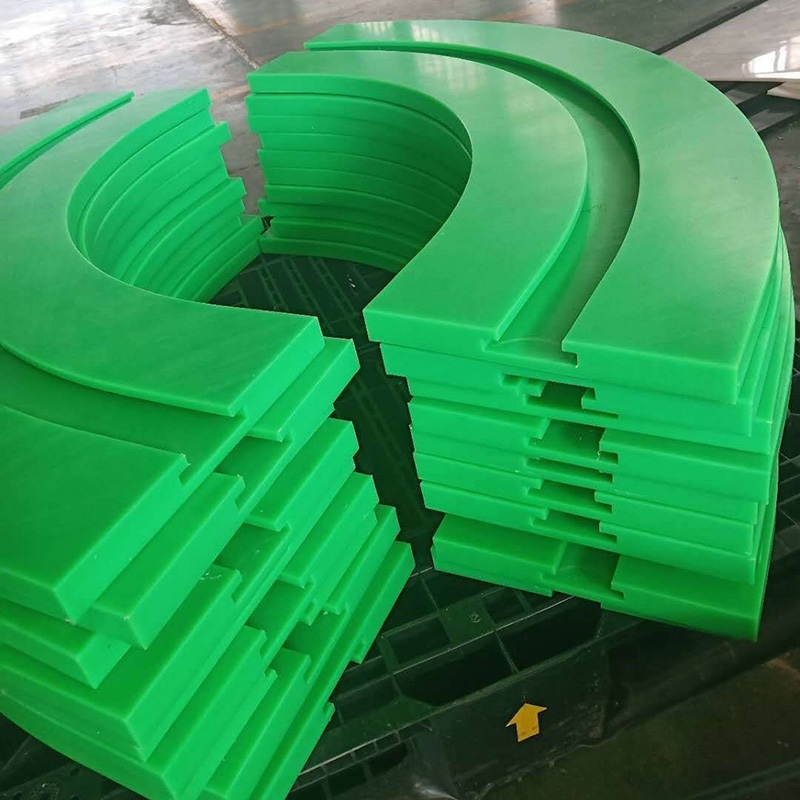

Among the plastics used by Chain Guides, ultra-high molecular weight polyethylene (UHMWPE) is an ideal choice.

UHMWPE has the following advantages:

Excellent wear resistance: It can effectively reduce the friction and wear between Chain Guides and guide rails and extend the service life of guide rails.

Low friction coefficient: make the chain more smooth during operation and reduce energy consumption.

Strong impact resistance: can withstand large impact force, not easy to damage.

Good self-lubrication: no need to add additional lubricating oil, reducing maintenance costs.

Excellent chemical resistance: can maintain good performance in a variety of chemical media environments.

Of course, in addition to UHMWPE, polytetrafluoroethylene (PTFE) is also a common material. PTFE has a very low coefficient of friction and good corrosion resistance, but relatively speaking, its price is higher and its strength is not as good as UHMWPE.

To sum up, in most cases, ultra-high molecular weight polyethylene is a better choice for Chain Guides, but the specific needs to be considered according to the actual application scenarios and needs.