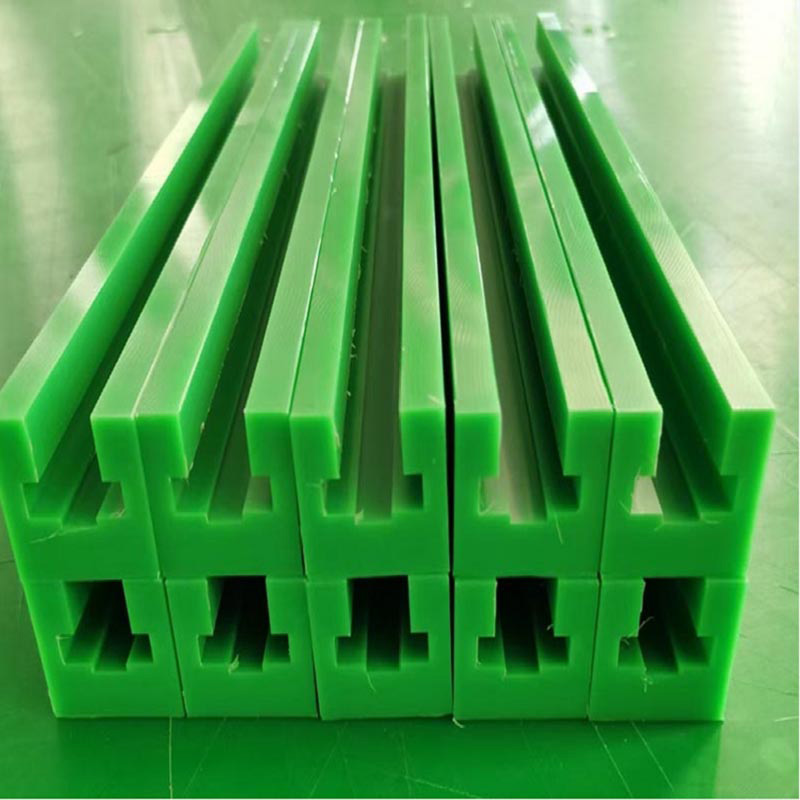

How is the wear resistance of UHMWPE Chain Track Guides

UHMWPE Chain Track Guide has extremely excellent wear resistance, which is mainly reflected in the following aspects:

Compared with other materials

Better than ordinary engineering plastics: The mortar wear index of ultra-high molecular weight polyethylene is extremely low, only 1/5 of PA66, 1/10 of PE-HD and PVC.

Surpassing some metals: Its wear resistance exceeds that of some metals, such as 1/7 of carbon steel and 1/27 of brass.

Determined by its own characteristics

Relationship between molecular weight and wear resistance: The wear resistance of ultra-high molecular weight polyethylene is proportional to the molecular weight. The higher the molecular weight, the better its wear resistance. Generally speaking, ultra-high molecular weight polyethylene with a molecular weight of more than 1.5 million has excellent wear resistance, and when the molecular weight reaches 3 million to 5 million, its wear resistance reaches an extremely high level.

Influence of molecular structure: UHMWPE Chain Track Guide has a linear molecular structure, and the molecular chains are entangled with each other. This special structure enables the molecular chains to slide relatively when the material is rubbed, thereby effectively dispersing stress and reducing wear. At the same time, the high degree of entanglement of molecular chains also makes the material have higher hardness and strength, which can withstand greater friction without deformation and wear.