Shengxing Shares Several Precautions For Installing Coal Bin Liners

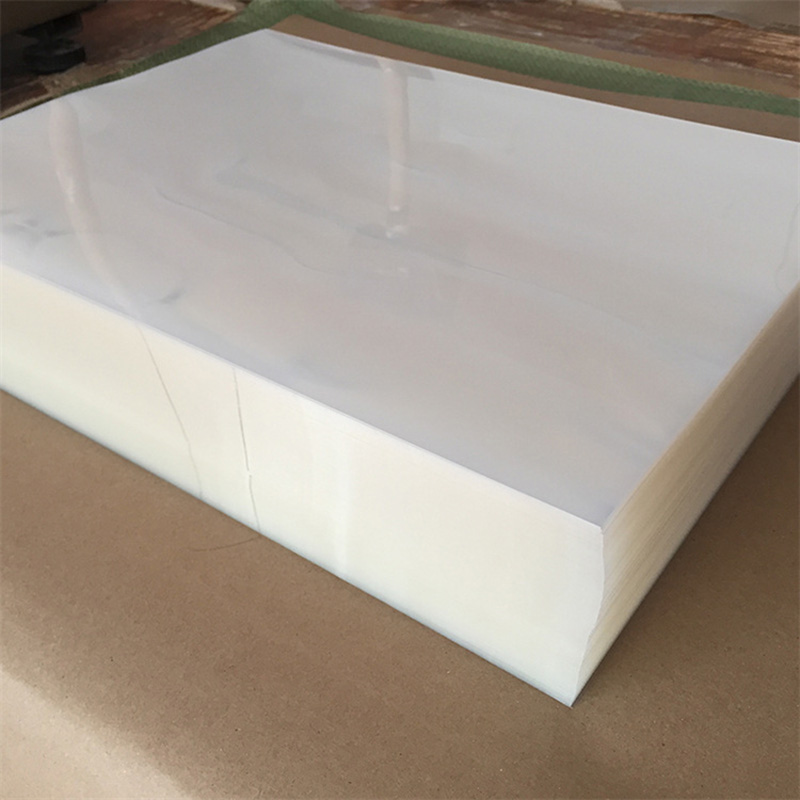

When carrying out the installation of coal bunker liners, it is necessary to take into account that the liner is fixed in such a way that it expands or shortens spontaneously in the event of a large change in operation or ambient temperature. Any kind of fixing method should be designed in such a way that it favours the movement of bulk materials and the screw head mother is always buried in the liner. In the case of thick liners, the joint edges should be cut at 45 degrees. In this way, the allowable length has changed, and in the silo constitute a smooth plastic plane, favourable to the activities of the material.

Installation of coal bunker liner special attention:

1, the installation process, the liner bolt countersunk head plane requirements are necessary below the plate surface;

2, coal bin liner product installation per square metre should not be less than 10 bolts;

3, each liner plate gap between the plates should not be greater than 0.5cm (device should be used according to the environmental temperature of the plate to give appropriate adjustment).